by Terry Bates, Luke Haggerty, Kevin Martin, Rhiann Jakubowski

Crop load management and crop estimation are central to control risk and maintain quality. Sensors technologies have the ability to gather relative vine size, soil, and yield data. The industry-based advisory committee has identified an opportunity to have the Lake Erie Regional Grape Program diagnose problems identified by sensor technologies in grower vineyards as the next critical step toward sensor technology commercialization. In this article we show an example of how sensor data and precision agriculture offer an opportunity to accurately estimate crop and continue to maintain the intensive management control that maximize yields and maintain vine balance. As long as bulk juice prices grow slower than inflation, the industry will depend on sustainable growth of vineyards to allow growers to farm full-time through multiple generations.

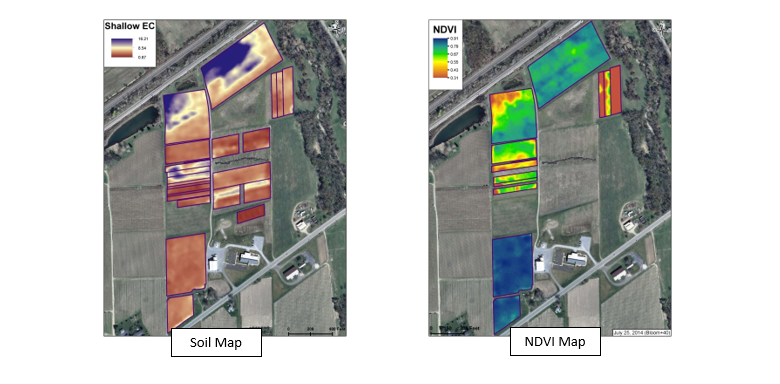

Sensor technology and GIS mapping projects continue to capitalize on recent research of sensors and software that gather and aid in the interpretation of vineyard variability. While the GIS Vineyard Mapping Project grew throughout 2014, area grape growers were also educated about the Vineyard Sensor Technology project during Coffee Pot meetings, Grower Conferences, and other various meetings during the season. Growers were encouraged to sign up to have a canopy sensor driven through their vineyards to collect data on NDVI (Normalized Difference Vegetation Index), a measurement of canopy growth, at different stages during the growing season. As sensor technologies takes hold in the region, we have seen increased interest from area growers. Overall, 18 grape growers covering a total of 450 acres accepted the opportunity to have their vineyards sensed. Maps generated from the data collected were implemented into decision making and aided growers in crop estimation practices by showing the visual differences within their vineyard blocks.

Comparing Methods for More Accurate Concord Crop Estimation:

Crop estimation is important at the farm level to make appropriate management decisions on crop adjustment, resource inputs, harvest needs, and harvest scheduling. In 2014, the economic impact of inaccurate crop estimation was also seen at the industry level, where extra costs were incurred for juice storage and shipping because the crop was larger than expected.

In 2014, we compared three different techniques for crop estimation at CLEREL and compared the estimates with the actual harvest weights from the processor scale house and a harvester-mounted grape yield monitor. First, we followed our developed method for sampling the vineyard by clean picking two panels (1% of an acre at our row and vine spacing), weighing the fruit from those two panels, and multiplying that weight by a berry weight factor to calculate a final harvest weight (Figure 1). At CLEREL, we did not address crop estimation until 50 days after bloom (not the typical 30 days after bloom) because of conflicts with other research activities; therefore, we were between 65-70% of final berry weight (not the typical 50% at 30 DAB).

Figure 1: Crop estimation sampling 30-50 days after bloom. Approximately 1% of an acre is clean picked and weighed. The current crop weight is multiplied by a berry weight factor and sample size factor to calculate a harvest estimate in tons/acre. In 2014, crop estimation at CLEREL was done at 50 DAB (August 4, 2014), approximately 65-70% final berry weight, and we used a berry weight multiplication factor of 1.4-1.5 (100/70 = 1.43).

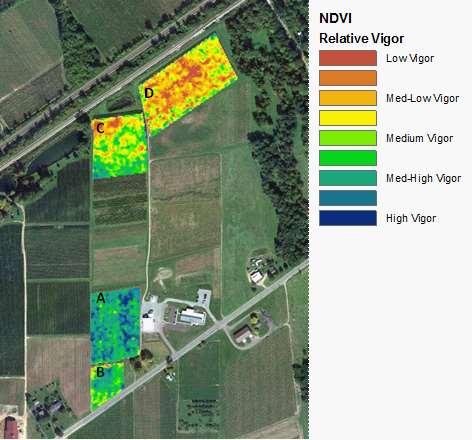

We collected 16 samples over 16 acres of grapes. Typically, this would be done randomly with the hope that the small sample size would accurately represent the whole vineyard. In 2014, canopy sensor measurements (NDVI) were collected at 20, 30, 40, and 50 days after bloom. The 20 DAB NDVI spatial map was used to designate three vine vigor classifications (low, medium, high). The 16 crop samples were stratified across the three classifications (Figure 2) and a mean crop estimate was generated for each classification.

Figure 2: A map of CLEREL vineyards depicting the NDVI generated vigor classifications (colors) and sample locations (black dots).

The harvest crop estimate was calculated three ways: a single mean, three vigor classes, and continuous with NDVI (Figure 3). In the “single mean” method, the average from the 16 vineyard samples (8.57 tons/acre) was simply applied to the total acres (16.12 acres). In the “three vigor class” method, the mean from the samples in the low vigor zone was applied to the acres of the low vigor zone, the mean from the medium vigor samples was applied to the acres of the medium vigor zone, and the mean from the high vigor samples was applied to the acres of the high vigor zone. In the “continuous with NDVI” method, the

linear relationship between NDVI and predicted yield in the 16 samples was determined and the mathematical relationship was applied back to the spatial NDVI map to generate a spatial predicted harvest map and overall crop estimate. The harvest estimates were compared to the actual harvest weights collected from a harvester-mounted grape yield monitor calibrated against actual truck weights at the scale house.

The actual yield from CLEREL in 2014 was 133.8 tons (Figure 3). Using the single mean method and assuming crop estimation was done between 65-70% of final berry weight, the crop estimate was between 138-148 tons (3.3-10.6% high). The three vigor class method estimated between 133-143 tons (0.1-7.2% high) and the continuous method estimated 137-145 tons (2.59.8% high). Therefore, using the NDVI generated vigor zones and assuming 70% of final berry weight at 50 days after bloom (a berry weight factor of 1.4) gave the most accurate crop estimate.

Figure 3: Crop estimation and actual yield maps including the relationships used to calculate the estimates. The numbers represent the harvest tons estimated on 16.12 grape acres and the percent the estimate was off from the actual harvest weight.

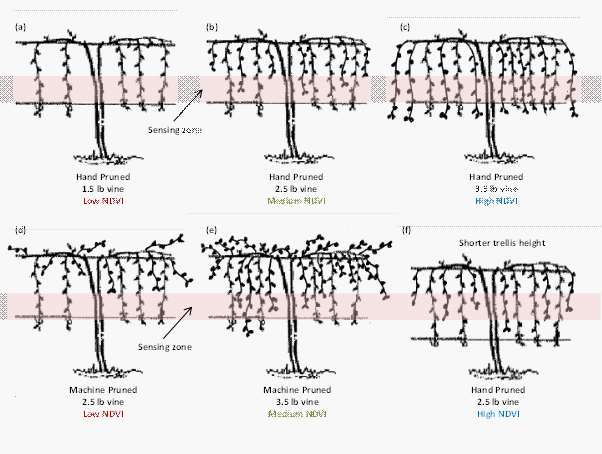

Similar to the curve-linear relationship between vine pruning weight and yield, vine yield increased with increasing NDVI values until the canopy was full and maximum light interception was reached. Higher NDVI values did not translate to higher yield. The “three vigor class” method, although coarse with only three means, approximated the actual curve-linear NDVI-Yield relationship more than the “continuous by NDVI” method, which assumed a strictly linear relationship. Therefore, the continuous method overestimated crop size at very high NDVI values.

Although we measured berry weight at crop estimation time and at harvest, it is interesting to note that we did not need berry weight measurements for any of these methods. We used the days after bloom and the standard berry curve in Figure 1 and made the assumption that the berries were 65-70% of final weight.

Economics of Sensor Driven Crop Estimation:

The commercialization of sensor technology requires a capital investment by the grower. Sensor packages used in this project are commercially available for $13,000. To cover 50% of the acreage in the region with this sensor package a total industry investment of $1.5 million would be required. The industry benefits of using this method of crop estimation, compared with grower results are likely to exceed $1 million in 2014. This is in a year when virtually 100% of the crop reached maturity. The economic impact of sensor driven crop estimation has much greater potential in higher risk years.

As our understanding of sensor technology advances, so to do potential uses. The use of sensor technology can decrease the cost of crop estimation by 50% or $2.50 per acre. While the cost of yield estimation is insignificant, a decrease in the labor associated with the practice increases the likelihood that growers will estimate their crop. A grower using NDVI to assist in crop estimation had a final crop size within 3% of their estimate.

For the Lake Erie Region, 2014 crop estimates were 80% of actual. Nationwide averages were 90% of actual. This creates serious financial and production risk to growers. Grower-owned processors incurred significant increases in containment costs that could have been avoided by simply understanding the size of the crop. In the Lake Erie Region, inaccurate crop estimation even resulted in the non-delivery of marketable tonnage. Further, there are also significant production risks associated with over-cropped vines that cannot be remedied unless the grower knows his crop size.

We have identified the $400,000 in costs to the industry. In all likelihood, because of proprietary processor information and return crops for 2014, the actual costs are significantly higher.